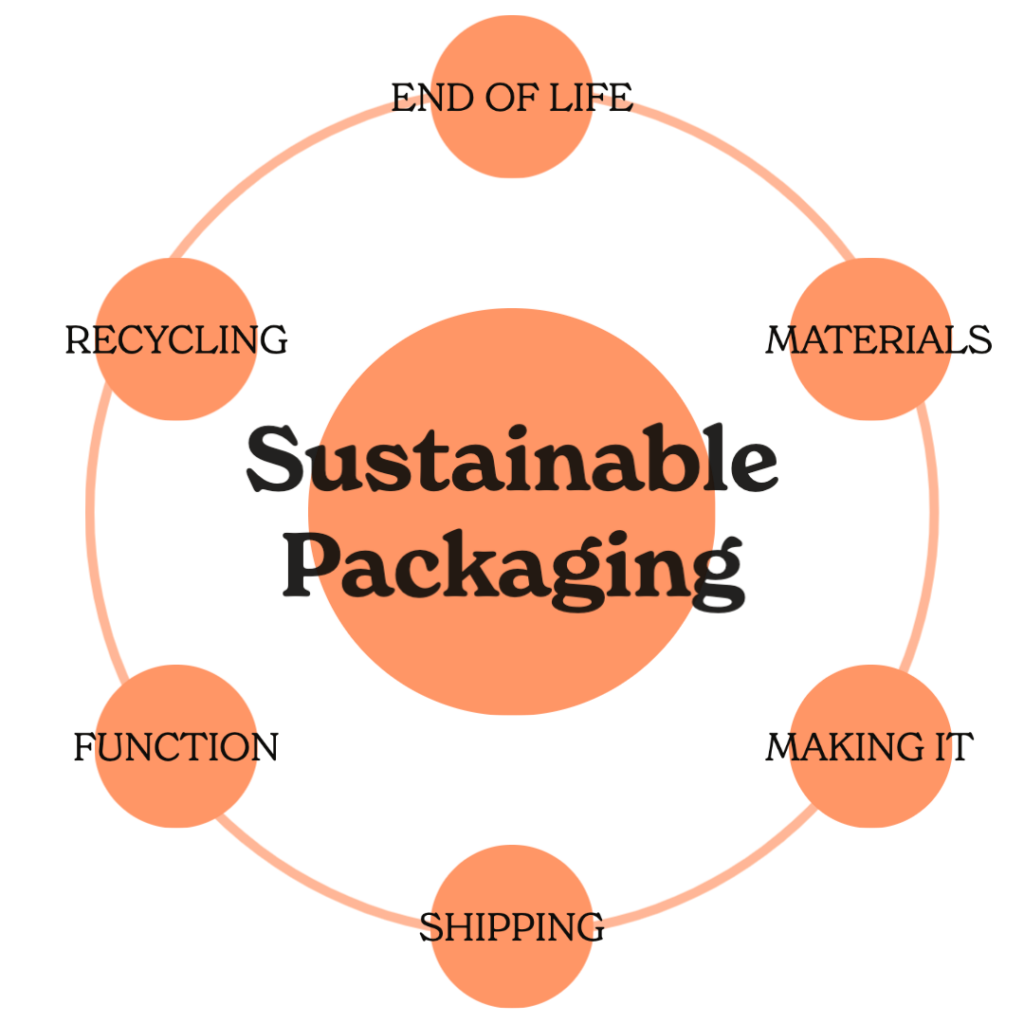

Are you looking for ways to make more sustainable decisions for your product packaging? In this article, you’re going to get a solid foundation in sustainable design thinking – the knowledge to empower you to make good choices.

The packaging for your product can have a huge carbon footprint. Consumers are increasingly choosing companies with environmentally friendly packaging. But what to choose? It can feel overwhelming choosing the right green packaging solution, with so much information out there. My Sustainability Choices Selector makes it easy!

Step 1: Raw materials – what your package is made out of

Different materials have different impacts on the earth. Some packaging is made out of plastic, which comes from oil. Some packaging is made out of hemp plastic that’s plant based. One creates pollution and fossil fuels that won’t be available for much longer, while the other actually binds excess carbon out of the atmosphere as it grows, which is a great thing, and can be grown again and again since it’s a renewable resource.

Plant-based renewable materials:

- Hemp or corn based bioplastics

- Paper (wood, bamboo, hemp, or post-consumer recycled paper)

- Cardboard

- Wood

- Fibers like bagasse and molded pulp

Non-renewable materials

- Petrochemical / oil based plastic

- Glass

- Metals

Step 2: How packaging is manufactured

This step can be the hardest for a normal person to figure out, and a reason you’d need a professional packaging designer to help you with your packaging project.

Different manufacturing methods have different size footprints. Some things are easier to make than others. For example, making new, virgin aluminum, like aluminum cans are almost always made with bauxite, a mineral that is really resource intensive to gather up, and is usually done with open pit mining under dubious environmental and health oversight.

Plastic manufacturing starts off with oil and natural gas which obviously has a big impact on the planet.

Glass takes huge heat and resources to mold. It’s done by using liquefied sand, soda ash, and quarried limestone, all having to be mined from the earth and heated up to form glass.

Resource intensive manufacturing materials:

- Glass

- Aluminum

Step 3: Transportation, the hidden carbon footprint of packaging

When getting from here to there, each container has a different footprint. The shipping alone can have a bigger carbon footprint than anything else combined. Consider this the next time you’re evaluating whether to buy packaging shipped from overseas, or choosing an option manufactured in the USA.

There’s one big, undeniable, eco-unfriendly aspect of glass bottles — they’re heavy and fragile. Shipping them from overseas has huge repercussions on the environmental aspects of your packaging.

Lightweight materials that are easier to ship, or shipped flat, will be better than things that require lots of padding and extra packaging for shipment and breakage.

Packaging that can be manufactured in the USA:

- Paper and cardstock

- Plastic

- Cardboard tubes and boxes

Packaging that is typically made in China:

- Aluminum

- Glass

- Rigid boxes

Step 3: Where They End Up – end of life and the sad truth about recycling

A lot of people think that if an item is recyclable, that equals sustainable. But recycling is just a small fraction of the sustainability footprint.

I’ll start with the bummer news: a lot of our recycling in the US is wish cycling. You put it in the magical blue bin, and hope it gets recycled. But a lot of the time, it won’t. And that’s if your local municipality offers recycling. Take for example the recycling rate of plastics, it is actually quite low — in 2014, only 9.5 percent of plastic material generated in the U.S. was recycled. Rest is in landfill. And in landfill, it will take at least 500 years, if not longer before finally decomposing.

Glass is recyclable, right? Except when it isn’t.

Glass bottles are 100 percent recyclable and an estimated 80 percent of recovered glass containers are made into new glass bottles. Once you toss your glass bottle in the recycling bin, manufacturers can have it back on the shelves in a month. Plus, using recycled glass when making new glass bottles reduces the manufacturer’s carbon footprint — furnaces may run at lower temperatures when recycled glass is used because it is already melted down to the right consistency.

BUT. And this is a big but. The most recyclable glass are big things, like beverage bottles, wine, beer etc. A lot of cannabis (and beauty packaging) is much smaller. The smaller the piece, the less likely it will end up recycled. A lot of cannabis packaging regulations require opaque glass. Brown and green glass are the colored glass most often approved for recycling. So when we choose to use “odd” colored glass like white milk glass containers, or black matte glass, those items will most likely not end up getting recycled in the normal recyclables waste stream.

With the added issue of states, like California, actually making all cannabis packaging “toxic waste” that is not technically allowed in the recycling stream due to contamination.

What about aluminum and metal recycling?

Like glass, aluminum cans are completely recyclable and are commonly recycled worldwide as part of municipal recycling programs. Aluminum cans can be recycled repeatedly with no limit. In her book (also now a movie!), The Story of Stuff, Annie Leonard notes that we are currently recycling only 45 percent of cans. That means a lot of pit mining for bauxite to make new material. According to Leonard, humans have trashed more than a trillion aluminum cans in landfills since 1972, when such records began.

Good things to do for the planet: Lightweighting packaging, reducing packaging

So what should one do? What is the most sustainable packaging?

The most sustainable packaging is no packaging at all. Since that’s not something that’s available for us as an industry, what can we do?

Less is more. Do you really need to put the oil in a vape pen and the vape pen in a heavy plastic case with a foam insert, inside a foiled cardboard keepsake box with a magnet closure? Probably not. You can achieve high end looks while utilizing renewable materials.

Also plan for your packaging suite to be modular – instead of buying a 100,000 boxes at a time custom printed for one batch and tossing them when that batch is over, maybe you can do the same with stamping or laser printing onto the boxes, or with labels? Less waste is sustainable. Direct printing on packaging can eliminate the need for separate labels, which in turn will help with the recyclability of your container or box.

Good things to do for the planet: Analyze and ask questions about manufacturing and materials

Bigger companies hire consultants to do life cycle analysis (LCA) on their products. This is a method used to quantify the environmental impact of a product throughout its life-cycle from raw material sources all the way to end-of-life of the product.

But in a low tech way, you can do a pros and cons list for different materials. (Or hire someone like me to do it for you). For example, when deciding whether to use packaging material from renewable sources but spending more energy in its shipping, or whether to use a material from a non-renewable resources but that can be produced with very little energy consumption locally, that’s a choice you can weigh for yourself.

Sustainability means different things for different people. Budget and shelf appeal do also play a part.

Good things to do for the planet: Recycle and reuse, advocate for sensible regulations

Our best deepest green hope as the cannabis industry is to look for packaging that is reusable and not disposable. There are some companies working on that, similar to how you can get food delivered in reusable containers, and can now buy refill pods for deodorant.

You’ve made the first step towards packaging sustainability for your cannabis company.

Let me help you take the next steps: